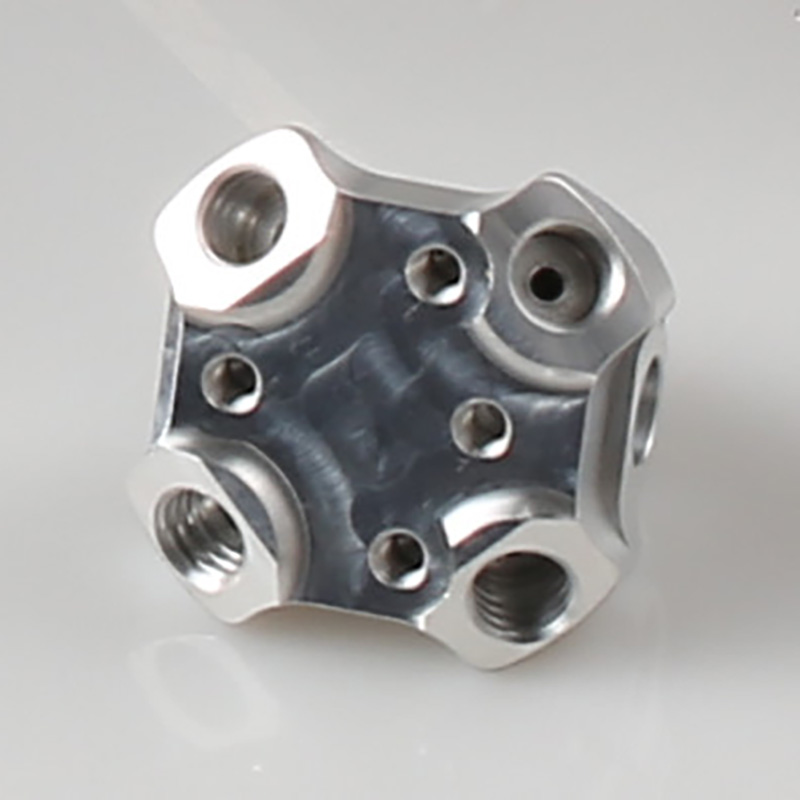

Re thabela ho hlahisa lihlahisoa tsa rona tsa tšepe tse sa hloekang tsa CNC tse nepahetseng, tse entsoeng le ho etsoa ho sebelisoa theknoloji ea morao-rao le thepa ea boleng bo phahameng.Fekthering ea rona, re sebelisa litsi tsa machining tsa Mazak CNC, litsi tsa Brother Turn-mill, LiTZ, le lisebelisoa tse ling tse tsoetseng pele tsa CNC ho netefatsa hore sehlahisoa se seng le se seng seo re se etsang se nepahetse le ho nepahala.

Bohlale ba rona bo mabapi le ho sila ka mokhoa o nepahetseng oa CNC, ho re fa monyetla oa ho bopa ka hloko lisebelisoa tsa tšepe tse sa hloekang ka ho nepahala ho isa ho 0.01 mm.Boemo bona ba ho nepahala bo netefatsa hore lihlahisoa tsa rona li fihlela litlhoko tse thata ka ho fetisisa, li fana ka boleng bo ikhethang le ts'ebetso.Ho phaella moo, bokhabane ba rona bo fihla ho Ra0.4, ho netefatsa phello e phethahetseng ea holim'a metsi le ho ntlafatsa botle ba kakaretso ea sehlahisoa.

Mechini ea rona e na le 3-, 4- le ka nako e le 'ngoe 5-axis milling bokhoni ba ho amohela mefuta e fapaneng ea lihlahisoa tsa lihlahisoa.Ho feto-fetoha ha maemo hona ho re lumella ho etsa mesebetsi e rarahaneng ea machining ha re ntse re boloka maemo a holimo ka ho fetisisa a ho nepahala le ho sebetsa hantle.Re ikamahanya le litlhoko tse ikhethang tsa sehlahisoa ka seng, re fana ka litharollo tsa moetlo tse fihlelang le ho feta litebello tsa bareki ba rona.

Ka ho sebelisa theknoloji ea morao-rao ea CNC ea ho sila, re khona ho fana ka lihlahisoa ka mokhoa o nepahetseng, ka nepo le ka nako e telele.Ebang ke lisebelisoa tse rarahaneng bakeng sa lisebelisoa tsa sefofane, lisebelisoa tsa bongaka tse nepahetseng kapa likarolo tsa koloi tse sebetsang hantle haholo, re na le bokhoni ba ho finyella litlhoko tsa hau hantle.