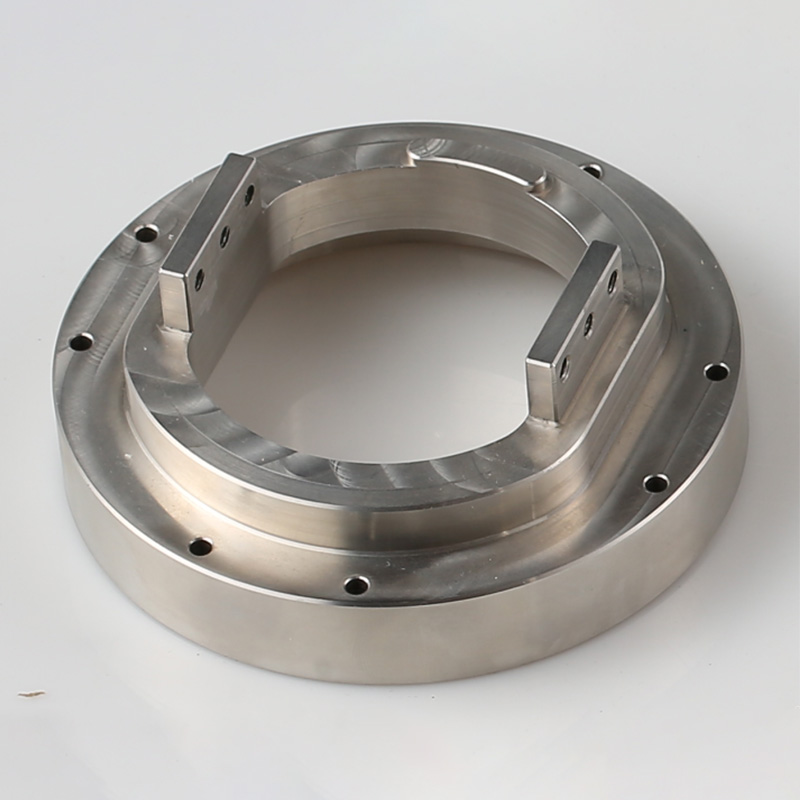

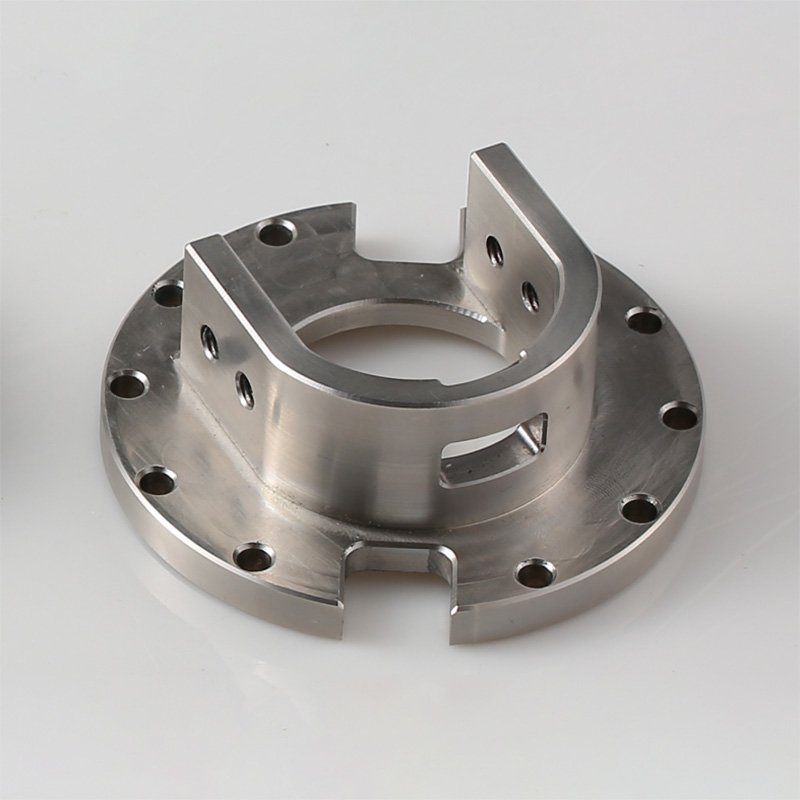

At our company, we pride ourselves on providing high quality precision CNC turning and milling services for carbon steel products. With the help of state-of-the-art CNC equipment, including Mazak dual-spindle turn-mill centers, Brother turn-mill centers, Star CNC turning centers, Tsugami CNC turning centers, etc., we are able to achieve superior accuracy and surface quality.

Our CNC turning and milling machines are capable of achieving shape and position accuracy within 0.01 mm, ensuring each product meets the strictest industry standards. Additionally, our machines can achieve surface roughness up to Ra0.4, giving our carbon steel products a smooth and visually appealing finish.

One of the main advantages of our CNC equipment is its versatility. With 3-, 4- and simultaneous 5-axis turning and milling capabilities, we can handle a variety of workpiece sizes. This flexibility allows us to meet our clients' specific requirements, regardless of the complexity or size of their projects.

Whether you need small precision parts or large components, our CNC turning and milling services can meet your needs. With our advanced machinery and highly skilled operators, we are able to handle both simple and complex geometries with ease. Our team has extensive experience working with all types of carbon steel, ensuring that no matter the specifications of your project, we can deliver outstanding results.